Surplus Stock Clearance

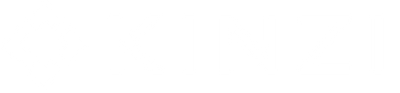

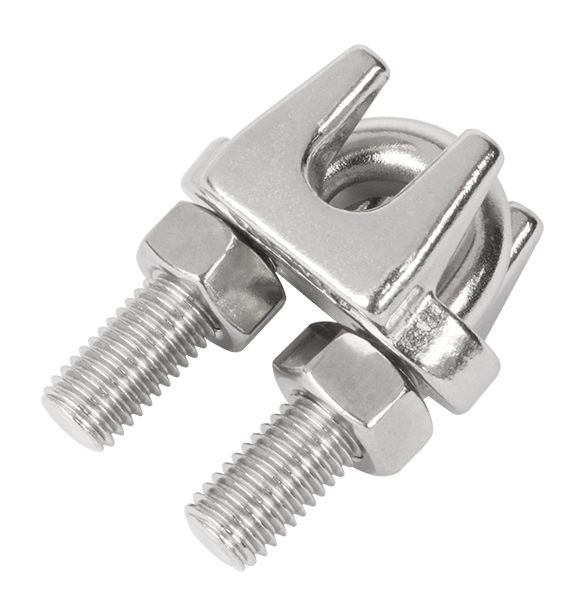

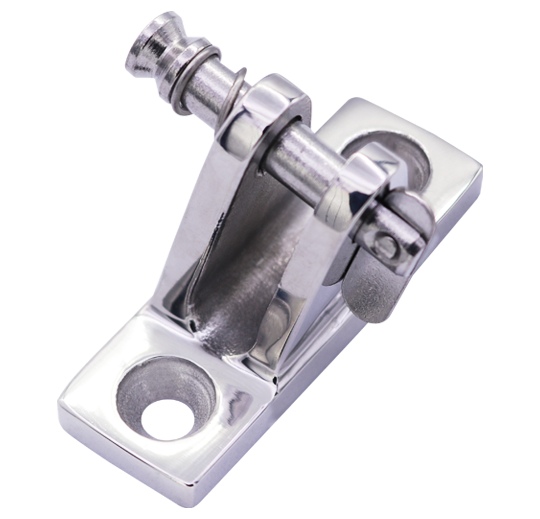

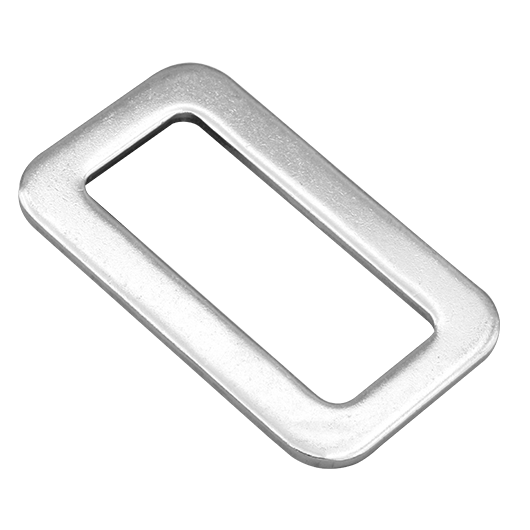

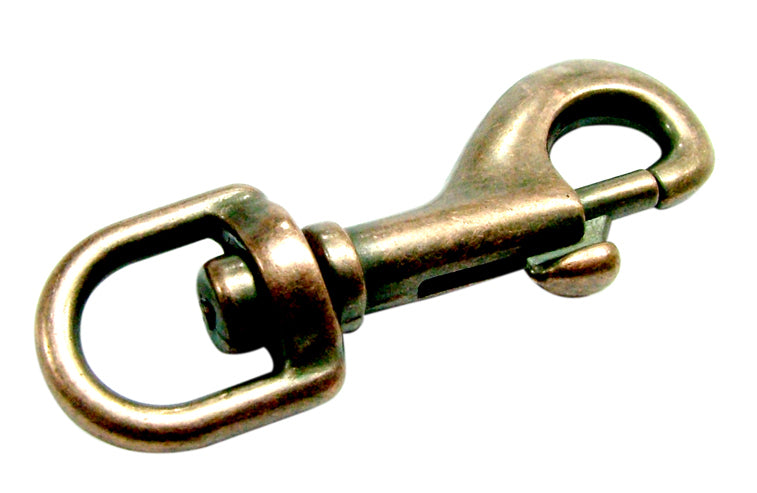

Kinzi has accumulated a surplus of its core products, including shackles, hooks, rings, and many more essential items for the marine, industrial, and architectural sectors. These products are only available to approved businesses. Pricing for available stock only - T&C's apply.