OEM PRODUCTS

YOUR STRATEGIC PARTNER IN STAINLESS STEEL HARDWARE

OEM Product

Kinzi work closely from concept to finished product. Designs are developed to align with production capabilities and cost effectiveness.With in-house engineering teams and mould production, the development process is controlled. Products need to be completed on time and within budgets. Kinzi understands our customers needs - Senior Managers have extensive experience in many industries supplied globally.

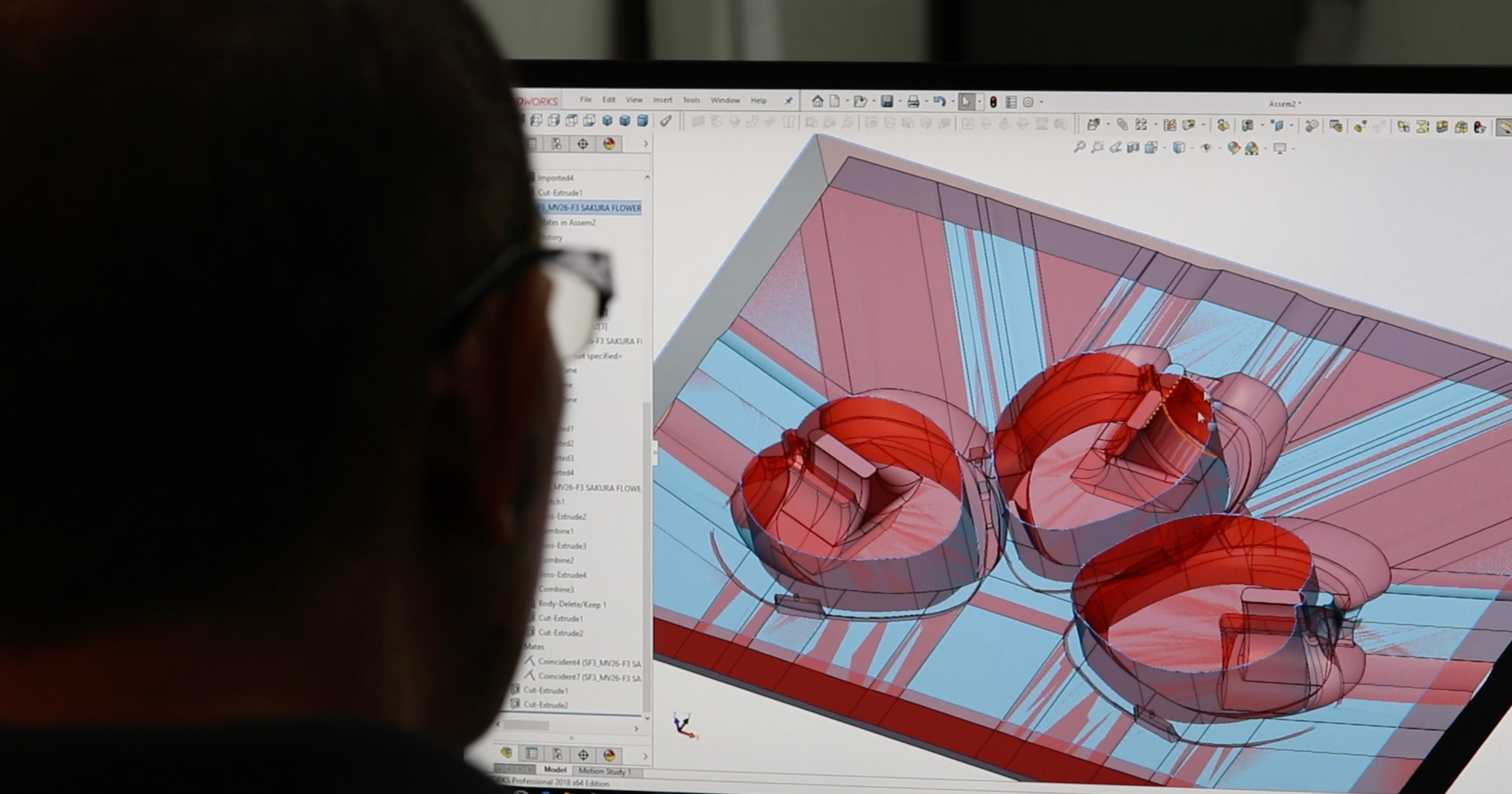

3D Rapid Prototypes

FEA Analysis

In-House Design & Mould Manufacture

Engineering & Design Team assist with OEM concept Design for Manufacture (DFM)

Performance by Design

With our in house design, engineering and mould facility we control the manufacturing process from concept to finished product. Kinzi are experts in stainless steel and great believers in form follows function.

With understanding of product applications we are able to develop products utilising the correct materials for the job and determine the most efficient production process.

Using Solid Works, Auto Cad and Magma casting simulation software. Finite element analysis, 3D printing and rapid prototyping ensure smarter decisions and efficient product development. Dimensions and consistency are critical. Our engineering team work hand in hand with our quality assurance team to ensure you have an identical product every time.

If you have a stainless-steel product design requiring a production solution, please get in touch.

Key Materials

AISI 316 & AISI 316L

AISI 304 & AISI 304L

17-4 PH

Duplex & Super Duplex

SS 400

Lead Time (Mass Production)

Casting 30 Days

Casting & Machining 45 Days

Casting, Machining & Mirror Polishing 60 Days

Lead Time (New Products)

Casting 60 Days

Casting & Machining 75 Days

Casting, Machining & Mirror Polishing 90 Days